Truly World-Class Internal (ID) Cylindrical Grinding Machines

The most common internal cylindrical (ID) grinding projects we see include workholding fixtures, various types of dies and gauges, and some medical applications, especially in the "radius" configurations of our ID grinding machines. The "radius" configuration of our ID cylindrical grinding machines denotes the ability of the workhead to swivel on the b-axis, allowing the machine to perfectly blend the geometry on the internal diameter of the workpiece with the face, creating a radius that is perfect for high precision die work as well as certain medical applications where spherical grinding is required.

Common Applications for STUDER Internal (ID) Cylindrical Grinding Machines

To get us started, here are five key considerations you should make when looking for your next external cylindrical grinding machine.

Collets

Collets are used in a wide array of manufacturing processes including grinding, milling, drilling, probing, and more. Their ability to precisely grip a workpiece or tool with an equal distribution of force requires maximum precision on the inside diameter.

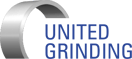

Ball Nut

A component of a ball screw assembly, the ball nut is the housing for the ball bearings, is typically made of steel and is designed to minimize friction between the ball bearings and the threaded shaft. The surface finish of the threads on the inside diameter of the ball nut is critical as higher quality surface finish results in smoother linear motion.

Drawing Die

A perfect example where our ID radius grinding machines excel, the drawing die is used to reduce the cross-section of material to a smaller dimension, or to change the shape or form of the starting material into an alternate shape. Our radius ID grinding machine configurations allow the workhead to swivel, creating a perfect blend between the ID and face of the die, resulting in supreme performance of drawing dies manufactured using these machines.

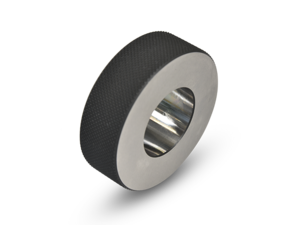

Ring Gauge

When high precision OD grinding processes occur, more often than not, ring gauges are used to measure the accuracy of these OD-ground workpieces. Since the ring gauge is itself an indication of another workpieces' dimensional accuracy, the ID of the ring gauge needs to be absolutely perfect. That's where STUDER ID grinders excel - creating the most accurate and precise parts time after time.

Hip Ball and Socket

These orthopedic implants are used in hip replacement surgeries around the world. The corresponding "socket" piece can also be ground on our ID-radius grinding machines. The perfect match of the ball and socket, and the use inside the human body require absolute precision when matching the geometry of the socket and ball - a job perfectly fit for the STUDER ID cylindrical grinding machines.

Are You New to Cylindrical Grinding?

You're in good hands. In fact, we have created the below article talking about what you need to know before you purchase your first cylindrical grinding machine. This is free to download, no form submissions required - just a gift from us to you. We hope this helps you organize your thoughts when it comes to important things to consider about your first cylindrical grinding machine. Enjoy!Our customers say it best...

Powerful technology backed by an incredible, US-based support team

It's no secret that STUDER CNC cylindrical grinding machines are known around the world for their extreme precision, accuracy, and repeatability. But what many people don't discover until they have the machine on their shop floor is how flexible the machine is - capable of changing between centers to chucked applications in minutes, allowing grinding shops to accommodate a wide variety of parts with a single machine. But don't take our word for it - listen to these customers tell how STUDER grinding machines have helped take their businesses to the next level:

C&S Machine Products, Inc.

An ultra-precision contract manufacturer based in Niles, MI has incorporated STUDER grinders into their production workflow and have seen some pretty stellar results.

Paramount Die Co.

Paramount Die relies on an automated production cell utilizing the STUDER S131r to grind drawing dies on a large scale, taking their die manufacturing to the highest level.

New England Die Company

Learn how Joe Almeida achieves world-class precision from his Waterbury, CT die shop, and how Joe has justified his STUDER purchase with lot sizes of 1 - 2 pieces per job.